Transformer wiring is crucial for safe and efficient electrical connections․ This guide provides essential insights, from basic principles to advanced configurations, ensuring proper setup and troubleshooting․

1․1 What is a Transformer?

A transformer is an electrical device that transfers energy between circuits through electromagnetic induction․ It consists of primary and secondary windings wrapped around a common core․ The primary winding is connected to the input voltage, while the secondary winding delivers the transformed voltage․ Transformers are used to step up or step down voltages, ensuring compatibility between different electrical systems․ They are essential in power distribution, industrial applications, and electronic circuits․ The voltage ratio between the primary and secondary windings determines the transformer’s output․ Available in single-phase or three-phase configurations, transformers are fundamental for efficient and safe electrical connections․ Understanding their operation is key to proper wiring and application in various systems․

1․2 Importance of Proper Transformer Wiring

Proper transformer wiring is critical for ensuring safety, efficiency, and reliability in electrical systems․ Incorrect wiring can lead to system failures, overheating, or even dangerous electrical hazards․ By following correct wiring procedures, you minimize the risk of faults and optimize performance․ Proper connections ensure that the transformer operates within its rated specifications, delivering the correct voltage and current levels․ This prevents damage to connected equipment and prolongs the transformer’s lifespan․ Additionally, correct wiring helps meet industry standards and safety regulations, protecting users from potential risks․ Regular inspections and adherence to manufacturer guidelines further ensure safe and efficient operation․ Proper transformer wiring is thus essential for maintaining system integrity and user safety․

Types of Transformers

Transformers vary in types, including single-phase and three-phase models, each designed for specific applications․ Single-phase transformers are ideal for residential use, while three-phase transformers handle industrial loads, ensuring efficient power distribution across various systems․

2․1 Single-Phase Transformers

Single-phase transformers are designed to operate with a single alternating current (AC) waveform, making them ideal for residential and light industrial applications․ They are commonly used to step down high voltage from the power grid to safer, usable levels for household appliances, lighting, and small machinery․ These transformers are simpler in construction compared to three-phase models, with only two windings: a primary and a secondary․ Their wiring is straightforward, involving basic connections between the input and output terminals․ Proper wiring is essential to ensure safe and efficient operation․ Single-phase transformers are widely used in applications where the power requirements are relatively low, such as in homes, small businesses, and individual electrical circuits․

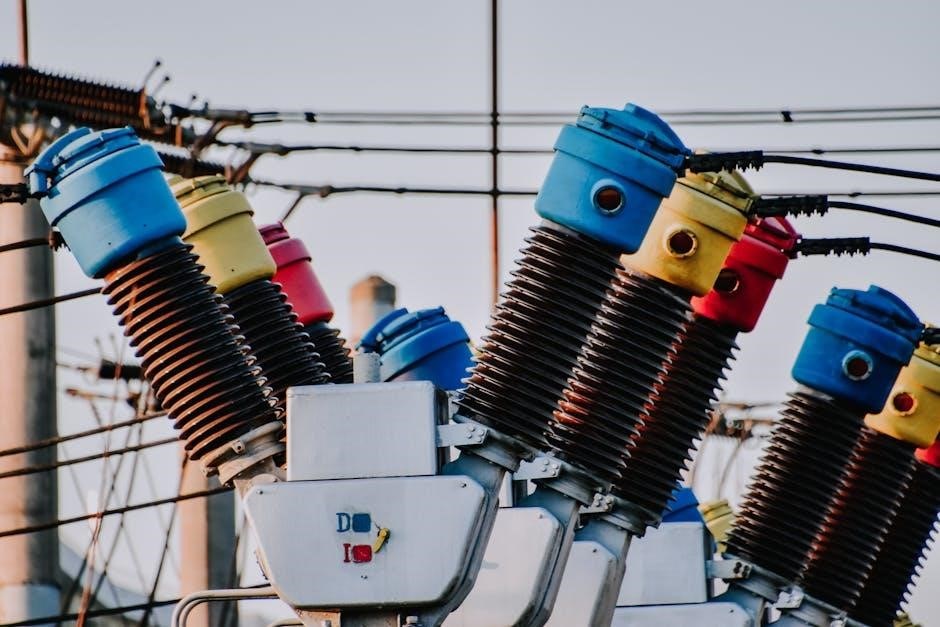

2․2 Three-Phase Transformers

Three-phase transformers are designed to handle three alternating current (AC) waveforms, making them ideal for industrial and high-power applications․ These transformers consist of three sets of primary and secondary windings, enabling them to manage larger power loads efficiently․ They are commonly used in factories, power distribution systems, and large commercial buildings where high voltage is required․ Three-phase transformers offer better efficiency and scalability compared to single-phase models․ Their wiring involves more complex configurations, such as delta and wye connections, which require careful planning to ensure proper phase sequencing․ This type of transformer is essential for applications where three-phase power is necessary, providing reliable and efficient energy distribution in demanding environments․

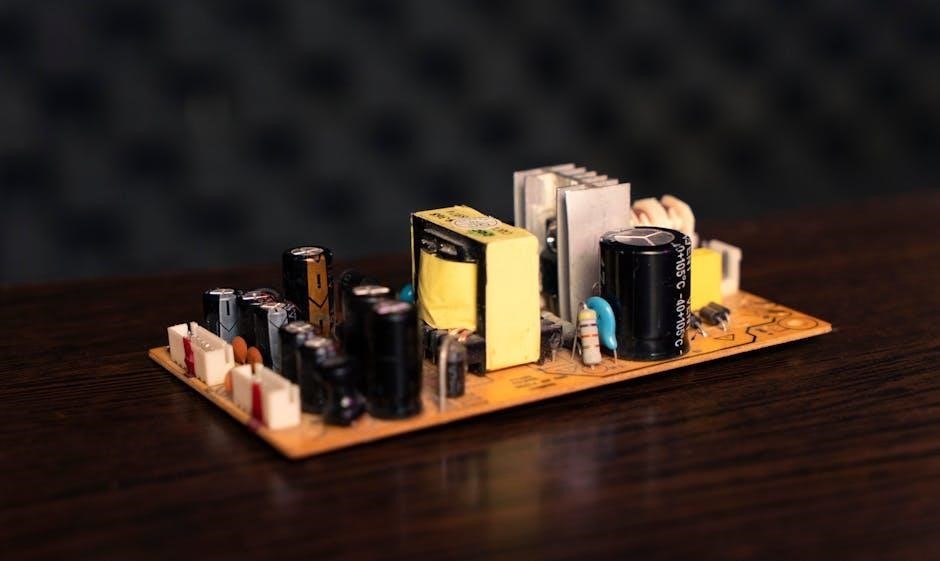

Transformer Wiring Diagrams

Transformer wiring diagrams provide a clear visual layout of primary and secondary winding connections, essential for safe and correct installation, and troubleshooting transformer wiring issues effectively․

3․1 Primary and Secondary Connections

Primary and secondary connections refer to the wiring setups on the input and output sides of a transformer․ The primary winding is connected to the power source, while the secondary winding supplies power to the load․ Proper connections ensure safe and efficient energy transfer․ Transformers can have multiple taps on the primary or secondary for voltage adjustments․ For single-phase units, connections are straightforward, while three-phase systems require careful phasing to maintain balance․ Correct polarity and voltage ratings are critical to avoid damage or malfunction․ Always refer to the manufacturer’s specifications for the correct configuration of primary and secondary connections to ensure optimal performance and safety․

3․2 Reading a Transformer Wiring Diagram

Reading a transformer wiring diagram requires understanding its symbols and notations․ The diagram visually represents the transformer’s internal and external connections, including primary and secondary windings, taps, and grounding points․ Start by identifying the input (primary) and output (secondary) sides, labeled clearly․ Look for color-coded wires or lines, which indicate different phases or connections․ Pay attention to terminal markings, such as H1, H2 for primary and X1, X2 for secondary․ Arrows or dots may show current flow direction․ Always cross-reference the diagram with the transformer’s datasheet to confirm configurations․ This ensures accurate wiring and safe operation․ Proper interpretation is crucial for avoiding short circuits and ensuring the transformer functions as intended․

Safety Protocols in Transformer Wiring

Safety protocols in transformer wiring involve de-energizing circuits, using PPE, ensuring proper grounding, and following all relevant electrical codes to prevent hazards․

4․1 General Safety Precautions

When working with transformer wiring, it is crucial to follow general safety precautions to minimize risks․ Always de-energize the circuit before starting work and verify voltage absence using a multimeter․ Ensure proper lockout/tagout procedures are in place to prevent accidental energization․ Wear appropriate personal protective equipment (PPE), such as insulated gloves and safety glasses, to protect against electrical shocks and arcs․ Keep the work area well-ventilated and avoid wearing loose clothing that could get caught in tools․ Use non-conductive tools and ensure all equipment is properly rated for the voltage levels involved․ Never work near open flames or sparks, as transformers can produce flammable gases under certain conditions․ Always follow manufacturer guidelines and local electrical codes to ensure safe practices․ Additionally, keep a fire extinguisher nearby and maintain a safe distance from energized components․ Proper training and experience are essential for handling transformer wiring safely․ Regularly inspect tools and equipment for damage or wear․ Working in a well-lit area is also important to avoid accidents caused by poor visibility․ Always ensure the transformer is properly grounded to prevent electrical hazards․ By adhering to these general safety precautions, you can significantly reduce the risk of injury or damage during transformer wiring tasks․ Proper preparation and awareness are key to maintaining a safe working environment․ Electrical work should never be rushed, and caution should always be prioritized․ Finally, never attempt to work on a transformer without proper training or supervision, as it can lead to serious electrical hazards․ Always refer to the manufacturer’s instructions for specific safety recommendations tailored to your transformer model․ This ensures compliance with safety standards and prevents potential hazards․ Remember, safety should never be compromised when dealing with high-voltage equipment like transformers․ Always stay alert and focused while performing any electrical work․ Following these guidelines will help protect both you and your equipment from damage․ In case of uncertainty, consult a licensed electrician or seek additional resources to ensure safe practices․ Safety protocols are in place to prevent accidents, so take them seriously and implement them rigorously․ Proper safety measures not only protect individuals but also ensure the longevity and reliability of the transformer system․ Always prioritize caution when working with electrical components, as even minor oversights can lead to dangerous situations․ By being proactive and prepared, you can create a safer environment for transformer wiring tasks․ This approach not only safeguards your well-being but also contributes to the overall success of the project․ Remember, electrical safety is a shared responsibility, and adhering to established protocols ensures the safety of everyone involved․ Never underestimate the importance of proper safety practices when working with transformers, as they are critical for preventing accidents and ensuring reliable operation․ Stay informed, stay safe, and always follow the guidelines provided by manufacturers and safety organizations․ This careful approach will help you navigate the complexities of transformer wiring with confidence and security․ Proper safety protocols are essential for any electrical work, and transformer wiring is no exception․ Always take the time to review and implement these precautions to protect yourself and others from potential hazards․ Electrical safety is not just a set of rules; it is a commitment to preventing accidents and ensuring a safe working environment․ By taking safety seriously, you can avoid costly mistakes and ensure the integrity of your transformer system․ Remember, safety is everyone’s responsibility, and vigilance is key to avoiding electrical risks․ Stay safe, and always prioritize caution when working with transformers․ Proper safety protocols are designed to protect you and your equipment, so take them seriously and implement them consistently․ This mindset will help you complete transformer wiring tasks efficiently and safely, ensuring a successful outcome every time․ Always remember that safety is the foundation of any successful electrical project, and transformer wiring is no exception․ By following established guidelines and taking necessary precautions, you can minimize risks and achieve your goals without compromising safety․ Stay informed, stay cautious, and always put safety first when working with transformers․ Proper safety practices are not optional; they are essential for protecting lives and ensuring the reliability of electrical systems․ Never overlook the importance of safety protocols, as they are your first line of defense against electrical hazards․ By prioritizing safety, you can create a secure and efficient working environment for all transformer wiring tasks․ Always stay vigilant and proactive in implementing safety measures, as they are critical to preventing accidents and ensuring successful outcomes․ Remember, safety is a shared responsibility, and your adherence to protocols contributes to a safer workplace for everyone․ Take pride in your commitment to safety, and let it guide your actions when working with transformers․ This dedication will not only protect you but also enhance the overall quality of your work․ Safety is the cornerstone of any electrical project, and transformer wiring demands the highest level of attention to safety details․ By consistently following safety protocols, you can navigate the challenges of transformer wiring with confidence and security․ Always prioritize safety, and never compromise on the precautions that protect you and others from electrical risks․ This approach will ensure that your transformer wiring projects are both successful and safe․ Proper safety practices are not just a recommendation; they are a necessity when working with high-voltage equipment like transformers․ By taking the time to implement these precautions, you can significantly reduce the risk of accidents and ensure a safe working environment․ Always remember that safety is a continuous process that requires attention and effort, but it is worth it to protect yourself and others․ Stay safe, and let safety guide your every action when working with transformers․ Proper safety protocols are in place to protect you, so take them seriously and implement them consistently․ By doing so, you can enjoy a safe and successful transformer wiring experience․ Safety is not just a set of rules; it is a way to ensure that you and others can work confidently and securely, knowing that risks are minimized․ Always prioritize safety, and never take unnecessary risks when working with electrical equipment․ This careful approach will help you complete transformer wiring tasks safely and effectively․ Remember, safety is everyone’s responsibility, and your commitment to it makes a difference․ Stay safe, and always put safety first when working with transformers․ Proper safety practices are essential for any electrical work, and transformer wiring is no exception․ By following established guidelines and taking necessary precautions, you can minimize risks and ensure a safe working environment․ Always stay informed, stay cautious, and prioritize safety in all your actions․ This dedication will not only protect you but also contribute to the success of your projects․ Safety is the foundation of any successful electrical project, and transformer wiring demands the highest level of safety awareness․ By consistently implementing safety protocols, you can avoid hazards and ensure a secure working environment․ Always remember that safety is not optional; it is a necessity when working with high-voltage equipment like transformers․ Take pride in your commitment to safety, and let it guide your actions․ This careful approach will help you navigate the challenges of transformer wiring with confidence and security․ Proper safety practices are not just a recommendation; they are a requirement for protecting yourself and others from electrical risks․ By prioritizing safety, you can create a safe and efficient working environment for all transformer wiring tasks․ Always stay vigilant and proactive in implementing safety measures, as they are critical to preventing accidents and ensuring successful outcomes․ Remember, safety is a shared responsibility, and your adherence to protocols contributes to a safer workplace for everyone․ Take pride in your commitment to safety, and let it guide your actions when working with transformers․ This dedication will not only protect you but also enhance the overall quality of your work․ Safety is the cornerstone of any electrical project, and transformer wiring demands the highest level of attention to safety details․ By consistently following safety protocols, you can navigate the challenges of transformer wiring with confidence and security․ Always prioritize safety, and never compromise on the precautions that protect you and others from electrical risks․ This approach will ensure that your transformer wiring projects are both successful and

4․2 Personal Protective Equipment (PPE)

Personal Protective Equipment (PPE) is essential for safeguarding against electrical hazards during transformer wiring․ Insulated gloves, rated for the specific voltage, protect hands from electric shocks․ Safety glasses or goggles shield eyes from debris or arcs․ A face shield offers additional protection, especially during high-risk operations․ Fire-resistant clothing, adhering to industry standards like NFPA 70E, protects against arc flash hazards․ Steel-toe boots prevent foot injuries from heavy tools or materials․ Ensure all PPE meets standards like ASTM or NFPA․ Regularly inspect PPE for damage, as compromised gear can fail during emergencies․ Always use PPE designed for electrical work to minimize risks effectively․

Step-by-Step Transformer Wiring Guide

Plan the installation, prepare tools, and ensure safety protocols are in place․ Connect primary and secondary windings according to the wiring diagram, test connections, and verify proper operation․

5․1 Preparing for Transformer Installation

Preparation is critical before starting transformer installation․ Begin by gathering all necessary tools and materials, such as wire cutters, voltage testers, and insulated gloves․ Review the wiring diagram to understand the connections․ Ensure the transformer is rated for the intended load and voltage․ Inspect the transformer and wiring for any damage or defects․ De-energize the circuit and verify zero voltage using a multimeter․ Wear appropriate PPE, including safety glasses and insulated tools․ Plan the workspace to ensure accessibility and proper ventilation․ Double-check local electrical codes and manufacturer guidelines․ Proper preparation ensures safety and a smooth installation process, reducing the risk of errors or hazards․

5․2 Connecting Transformer Windings

Connecting transformer windings requires precision to ensure proper functionality․ Start by identifying the primary and secondary windings using the wiring diagram; Connect the primary winding to the power source, ensuring the voltage rating matches the supply․ For the secondary winding, attach the load according to the desired output voltage․ Use appropriately sized wires to minimize resistance․ Ensure all connections are secure and insulated to prevent short circuits․ If the transformer has taps, configure them as needed for voltage adjustment․ Double-check all connections before energizing the circuit․ Test the transformer under load to confirm correct voltage and current output․ Always follow manufacturer guidelines and safety protocols when connecting transformer windings to avoid hazards and ensure reliable operation․

Troubleshooting Common Transformer Issues

Common transformer issues include faulty connections, overload, or short circuits․ Check connections, verify load, and test for insulation breaches using a multimeter․ Addressing these promptly ensures reliability and safety․

6․1 Identifying Faults in Transformer Wiring

Identifying faults in transformer wiring involves checking for open circuits, short circuits, or insulation failures․ Use a multimeter to test continuity and resistance in primary and secondary windings․ Look for signs of overheating, such as discolored or charred wires․ Verify that all connections are secure and free from corrosion․ Measure insulation resistance using a megohmmeter to detect any breaches․ Unusual odors or noises, like buzzing or vibrating, may indicate internal faults․ Always ensure the transformer is de-energized before performing tests․ Refer to the wiring diagram to trace connections and isolate potential issues․ Regular inspections can prevent minor problems from escalating into major failures․

6․2 Common Problems and Solutions

Common transformer wiring issues include overheating, voltage mismatch, and short circuits․ Overheating can result from overloaded circuits or poor ventilation; ensure proper cooling and reduce load․ Voltage mismatch occurs when primary and secondary voltages don’t align with requirements; verify ratings and adjust connections․ Short circuits often stem from loose or faulty connections; tighten terminals and replace damaged wires․ Insulation failure can cause leaks or arcing; replace worn insulation and ensure moisture protection․ For three-phase systems, incorrect phase connections can lead to imbalance; consult diagrams to confirm wiring sequence․ Regular maintenance and adherence to specifications help prevent these issues, ensuring safe and efficient transformer operation․

Transformer Applications

Transformers are essential in power systems for voltage adjustment and efficiency․ They are widely used in industrial, residential, and commercial settings to ensure reliable energy distribution and utilization․

7․1 Industrial Applications

In industrial settings, transformers play a crucial role in power distribution and voltage regulation․ They are used to step up or step down voltages to match the requirements of industrial machinery and equipment․ Factories and manufacturing plants rely on transformers to ensure efficient power supply for motors, pumps, and other heavy-duty applications․ Industrial transformers are designed to handle high power loads and provide reliable performance in harsh environments․ They are often used in power grids, industrial control systems, and large-scale machinery․ Proper transformer wiring is essential to maintain safety, efficiency, and operational consistency in industrial settings․

7․2 Residential Applications

Transformers are widely used in residential settings to ensure safe and efficient power distribution․ They are essential for stepping down high voltage from the power grid to the lower voltage required for household appliances, lighting, and electronics․ Residential transformers are often installed at the entry point of electrical services in homes․ They are also used in substations and distribution panels to regulate voltage levels․ Proper transformer wiring ensures reliable power supply for home systems, including HVAC, refrigeration, and entertainment systems․ Additionally, transformers are used in residential complexes and apartment buildings to manage shared power resources efficiently․ Safe and correct wiring practices are critical to prevent electrical hazards and ensure optimal performance․

Advanced Transformer Configurations

Advanced transformer configurations optimize performance in complex electrical systems․ These include parallel operation, delta-wye connections, and multi-winding setups, ensuring efficient voltage regulation and reliability․

8․1 Wiring Multiple Transformers in Parallel

Wiring multiple transformers in parallel is a method to increase the total power capacity of a system․ This configuration is commonly used in industrial applications where higher load demands exist․ To achieve this, transformers must have the same voltage ratings and impedance values to ensure proper load sharing․ The primary windings are connected to the same power source, while the secondary windings are combined to deliver the total power․ Key considerations include matching impedance, synchronizing phase angles, and ensuring equal voltage levels․ Proper balancing is critical to avoid uneven current distribution, which can lead to inefficiency or equipment failure․ Using busbars for connections enhances reliability and minimizes voltage drop․ Always refer to manufacturer guidelines for specific wiring recommendations․

8․2 Delta-Wye Transformer Configurations

The Delta-Wye transformer configuration is a common setup used to step down high-voltage three-phase power to lower voltages․ In this configuration, the primary windings are connected in a Delta (or mesh) arrangement, while the secondary windings are connected in a Wye (or star) pattern․ This setup provides a neutral point on the secondary side, making it ideal for applications requiring a stable neutral connection․ Advantages include high fault tolerance, reduced harmonics, and flexibility in voltage distribution․ Delta-Wye transformers are widely used in industrial and commercial power distribution systems, such as factories, large buildings, and data centers․ Proper phase alignment and voltage matching are essential for efficient operation․ Always follow manufacturer guidelines for specific wiring requirements․

Tools and Materials Needed

Essential tools include wire cutters, pliers, screwdrivers, and multimeters․ Materials needed are high-grade copper wire, insulation materials, and transformer oil for cooling․ Always ensure quality and safety compliance․

9․1 Essential Tools for Transformer Wiring

Proper transformer wiring requires specific tools to ensure safety and efficiency․ Essential tools include wire cutters, pliers, screwdrivers, and multimeters for measuring voltage and current․ A megohmmeter is necessary for testing insulation resistance, while a thermal imaging camera can detect overheating issues․ Torque wrenches are used for securing connections, and crimping tools are essential for creating reliable wire connections․ Safety tools like insulated gloves and goggles are critical for protecting against electrical hazards․ Additionally, a wire stripper and a set of precision tools for handling small components are often needed․ Using high-quality tools ensures accurate and safe transformer wiring, reducing the risk of errors or accidents․

9․2 Wire Size and Type Considerations

Choosing the correct wire size and type is crucial for safe and efficient transformer wiring․ Wire size must be selected based on the transformer’s current rating and voltage to avoid overheating and ensure optimal performance․ The American Wire Gauge (AWG) system is commonly used to determine appropriate wire sizes․ For high-current applications, thicker wires are necessary to minimize resistance and voltage drop․ Wire type, such as copper or aluminum, should be matched to the transformer’s specifications․ Insulation rating is another critical factor, as it must meet the transformer’s voltage and temperature requirements․ Proper wire selection ensures reliability, safety, and compliance with electrical standards․ Always refer to the transformer’s datasheet for specific recommendations․

Best Practices for Transformer Wiring

Best practices for transformer wiring involve adhering to manufacturer guidelines, ensuring proper insulation, and following safety protocols․ Regular maintenance and precise wire sizing are essential for optimal performance and longevity․

10․1 Following Manufacturer Guidelines

Adhering to manufacturer guidelines is crucial for safe and efficient transformer wiring․ Always refer to the specific instructions provided with the transformer, as these outline recommended wiring methods, voltage ratings, and connection configurations․ The manual typically includes diagrams, wire sizing charts, and safety precautions tailored to the device․ Deviating from these guidelines can lead to improper connections, reduced efficiency, or even safety hazards․ Pay attention to the recommended wire types, insulation levels, and tightening torque specifications to ensure reliable operation․ Additionally, follow any testing procedures outlined by the manufacturer to verify the integrity of the wiring before energizing the transformer․ This ensures compliance with industry standards and guarantees optimal performance․

10․2 Regular Maintenance Tips

Regular maintenance is essential to ensure the longevity and efficiency of transformer wiring․ Start by inspecting the connections and terminals for signs of wear, corrosion, or loose contacts․ Clean any dirt or debris that may accumulate, as it can cause overheating․ Check the insulation of wires for cracks or damage, and replace them if necessary․ Monitor the transformer’s operating temperature and ensure proper ventilation to prevent overheating․ Schedule periodic tests, such as voltage and current measurements, to verify optimal performance․ Additionally, keep the transformer and surrounding area free from dust and moisture․ Always follow the manufacturer’s maintenance schedule and guidelines to ensure safe and reliable operation․ Regular upkeep helps prevent failures and extends the lifespan of the transformer․